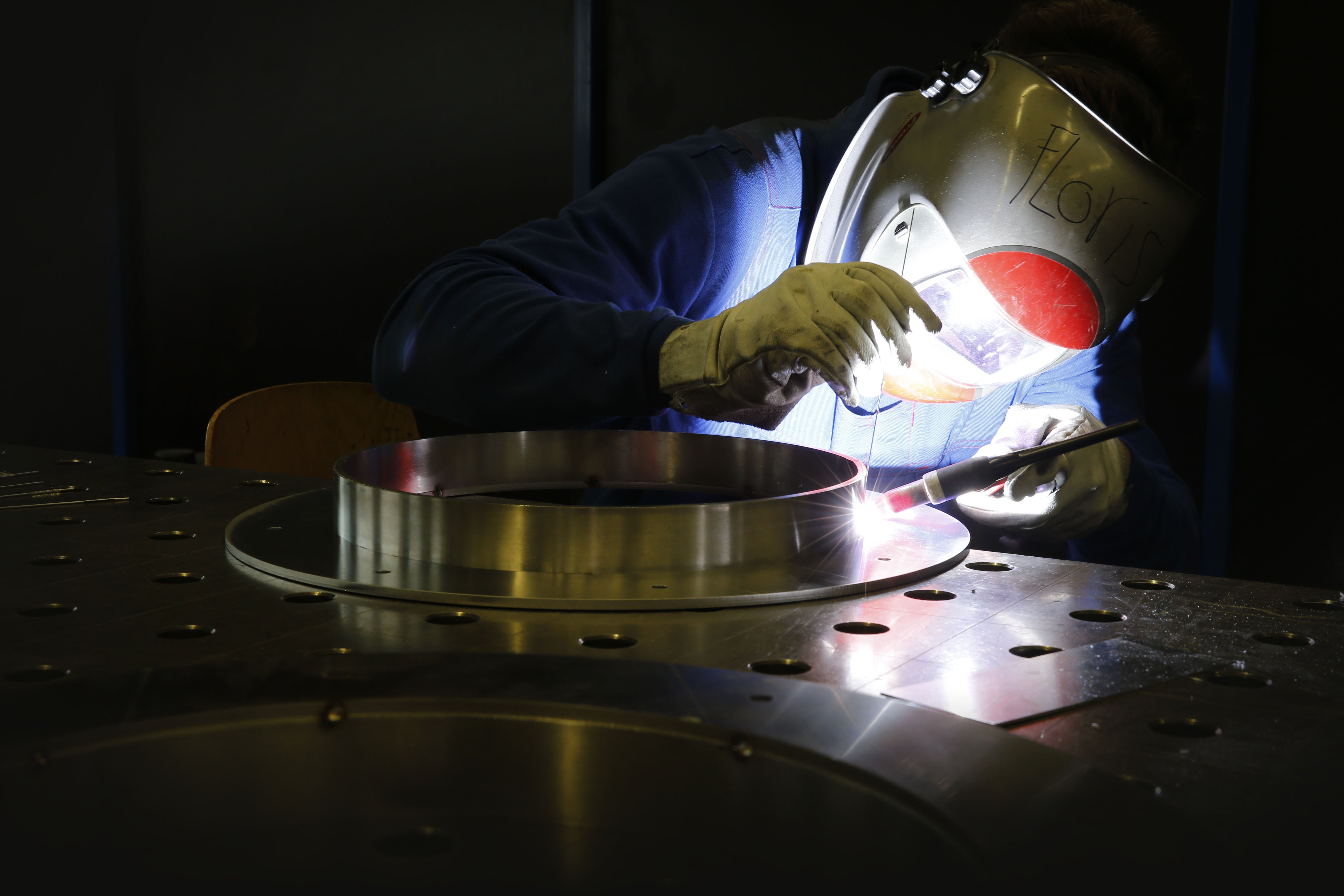

Welding and compiling

SNL Machine Construction a reliable supplier of system solutions in machine construction. We combine quality with flexibility and customisation, creating the best customisation systems, module construction, sub-assemblies and service-parts. We do this for Original Equipment Manufacturers in the food industry in particular. Our specialism is the development and manufacture of transport systems.

Our compilers/welders are genuine experts. When it comes to autonomously making machine or construction parts ready for welding or compiling and finishing operations with regard to welding, they always ensure high-quality customisation. All these parts are made from Inox profile and sheet material on the basis of drawings. Since many of these products will ultimately end up in the food industry, the highest quality will be expected. At SNL Machine Construction, we stand for the quality of our products. This is not achieved merely by our compilers/welders, but also as a result of our extensive and modern machine park.

Welding process

The welding process is an essential part of the procedure. Our welders are able to produce excellent welds. SNL Machine Construction is capable of performing different welding operations, such as:

- TIG

- MIG

- Stud welding

- Spot welding

At SNL Machine Construction we perform various operations, including welding. Our professional welders are familiar with different welding techniques and always manage to choose the correct implementation for your order.

TIG and MIG welding

TIG welding (Tungsten Inert Gas) is a special welding technique during which inert gas is being used. TIG welding is commonly used in the processing of, for instance (stainless) steel and aluminium. Since we work with high-quality Inox at SNL Machine Construction, we are specialised in expert TIG welding. TIG welding is done manually and with the greatest accuracy. High welding quality is guaranteed.

Another manual welding process that we, at SNL Machine Construction, specialise in is MIG welding. This commonly applied welding process is hugely versatile and fast. The level of our MIG welders is high, assuring you of excellent welding quality.

Orbital TIG welding

In some industries only the best welding quality is good enough. In those instances, for example in case of semi-conductors, pharmacy and the food industry, only the orbital system can be used. For that reason, orbital TIG welding is applied increasingly more often. Creating premium pipe connections using this technique is an easy task, partly because the orbital TIG welding process is fully automated. This process is applied specifically for the welding of round tubes and piping where prefect welding connections are required. During the process, the computer controlled welding head rotates 360 degrees around the weld, creating a continuous quality.

Orbital TIG welding increases the quality and reduces the costs

Orbital TIG welding has made us become a partner in process equipment with customisation in skid construction, small container construction and Inox piping. This could concern projects in the food, dairy, water, chemical, petrochemistry or pharmacy; SNL wishes to relieve its customers, from engineering up to manufacture and installation. Orbital TIG welding is an important part of that.

Compiling

A compiled metal product is a construction that is attached by means of welding processes. Our experienced welders are able to compile as well as weld constructions on the basis of drawings.